What equipment is required for small-scale river gold mining?

The core equipment for small-scale river gold mining is configured around two key processes: sand and gravel screening and gravity separation and purification. Auxiliary tools are also needed to ensure operational efficiency and safety. The detailed equipment list and their uses are as follows:

I. Core Gold Mining Equipment

1. Gold Pan

The most basic tool for manual gold mining, made of plastic or metal with corrugated bottoms. It works on the principle that gold has a much higher density than sand and gravel—gold particles are separated by shaking and rinsing the pan with water. Suitable for single-person, small-scale operations, it has extremely low costs and is ideal for beginners.

The most basic tool for manual gold mining, made of plastic or metal with corrugated bottoms. It works on the principle that gold has a much higher density than sand and gravel—gold particles are separated by shaking and rinsing the pan with water. Suitable for single-person, small-scale operations, it has extremely low costs and is ideal for beginners.

2. Portable Sluice Box

The core equipment for small-scale river gold mining, usually a long trough equipped with gold-catching mat/blanket. Sand, gravel and water from the river are poured into the sluice box together; flowing water washes away light sand and gravel, while gold particles are trapped by the riffles and gold mats.

-

Advantages: Enables multi-person collaboration, with a processing capacity more than 10 times that of gold pans.

3. Small Sand Suction Pump + Suction Hoses

Designed for river sections with deep water or thick sand-gravel layers, the pump extracts sediment from the riverbed and directly transports it to the sluice box for separation. It replaces manual shoveling, significantly improving efficiency and must be powered by a small generator.

4. Hand-Cranked/Electric Gold Centrifugal Concentrator

An advanced purification device that uses centrifugal force generated by high-speed rotation to quickly separate fine gold particles (suitable for recovering “flour gold”) from sand and gravel. It boasts much higher separation precision than sluice boxes, making it suitable for small-scale operations with a certain production scale, and requires a power source.

II. Auxiliary Tools and Equipment

1. Power Equipment

-

Small gasoline generator: Supplies power to sand suction pumps, centrifugal concentrators and lighting equipment.

-

Portable water pump: Draws water from the river to provide a stable water flow for the sluice box.

2. Sand and Gravel Pre-Treatment Tools

-

Screening sieve (with mesh size of 2–5mm): Filters out large cobblestones, branches and other impurities to prevent sluice box clogging.

-

Shovels and rakes: Used for manually shoveling sand and gravel, and clearing obstacles in the operation area.

3. Gold Particle Purification Tools

-

Gold-catching balls/paper: Absorbs fine gold particles from sluice boxes or centrifugal concentrators.

-

Electronic scale (with precision of 0.01g): Weighs recovered gold particles.

-

Sealed bottles/waterproof bags: Stores recovered gold particles to prevent loss.

4. Safety Protection Equipment

-

Non-slip waders and rubber gloves: Prevent slips during wading operations and hand scratches.

-

Safety helmets and life jackets: Guard against risks such as sudden surges or falling rocks in the river.

-

First-aid kit: Treats minor injuries.

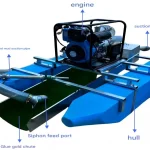

If the river is relatively large with abundant water flow, the best gold mining equipment is a gold dredge, which we will describe in the next article.