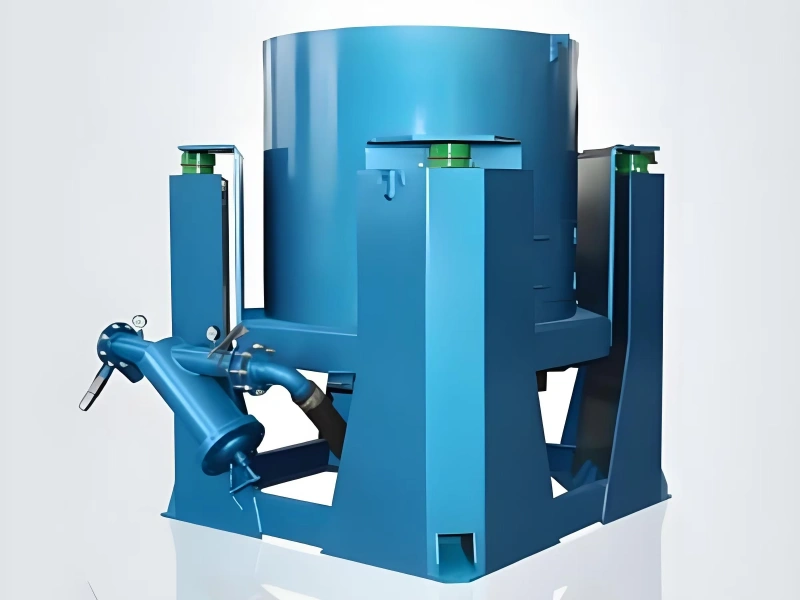

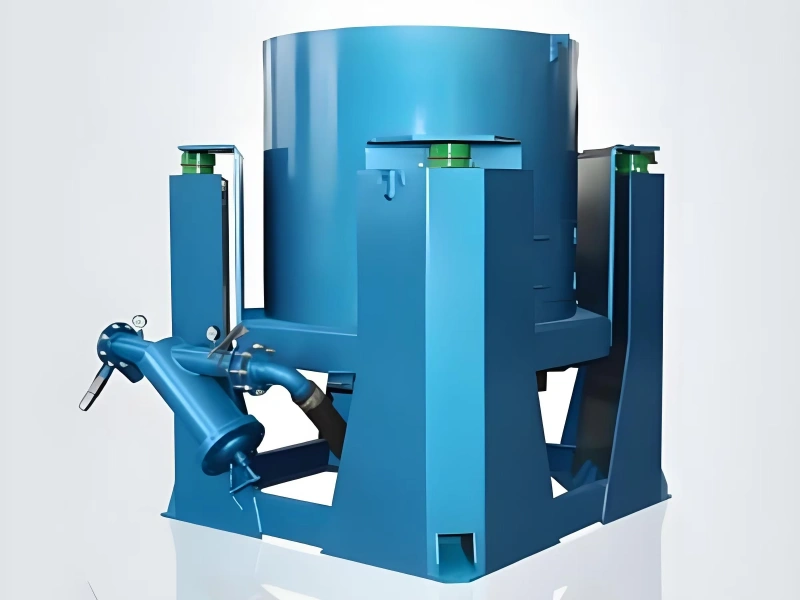

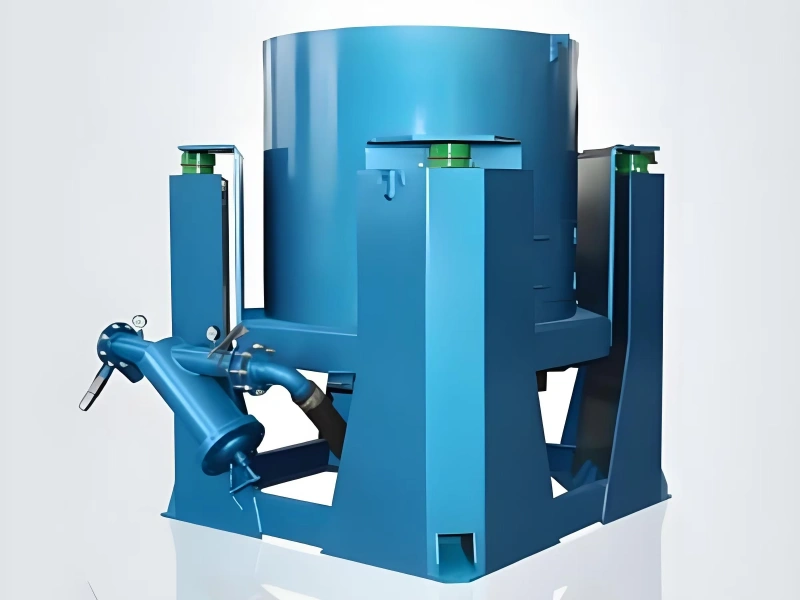

Water Jacket Gold Centrifugal Concentrator

| Product name: | Spiral Mineral Panning EquipmenT |

|---|---|

| Model Number: | QRUN wj11 |

| Production Capacity: | 3-120t/h |

| Weight: | 200-3000kg |

| Reverse Water Pressure: | 0.05-0.25MPa |

| Motor Power: | 3-22kw |

| Minimum Order Quantity: | 1 set |

| Delivery Time: | within 30 days |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Shipping Method: | Door to Door, Sea Freight |

The Water Jacket Gold Centrifugal Concentrator is a state-of-the-art gravity separation device designed specifically for gold beneficiation. Engineered to deliver exceptional performance in separating minerals of varying densities, it stands out as a reliable solution for enhancing gold recovery efficiency across diverse mining scenarios. Seamlessly integrable with existing production lines, this equipment is widely acclaimed for its eco-friendliness, cost-effectiveness, and operational stability.

Working Principle

The core operation of the water jacket gold centrifugal concentrator is driven by centrifugal force, ensuring precise and efficient separation:

- Ore slurry enters the bottom of the double-layer centrifugal cylinder through the upper feed pipe.

- Powered by a high-performance motor, the inner sleeve rotates at high speed, generating strong centrifugal force.

- Under the action of centrifugal force, heavy minerals (such as gold particles) are thrown into the gap between the inner and outer sleeves and move upward along the spiral grooves.

- When the heavy minerals reach the upper end of the cylinder, they are discharged from the heavy material outlet with the assistance of pressure water from the middle layer.

- Light minerals, meanwhile, are carried upward by the central upward water flow and discharged from the light material outlet.

- Pressure water is injected into the inner sleeve through small holes in the inner cylinder, forming a reverse water flow. This reverse flow effectively captures fine-grained heavy minerals, flushing the ore to ensure thorough separation and collection of target minerals.

Key Advantages

- High Separation Efficiency: Leverages advanced centrifugal technology to efficiently separate minerals of different densities, with exceptional performance in recovering high-specific-gravity gold particles.

- Superior Recovery Rate: Boasts an impressive gold recovery rate of up to 95%, significantly outperforming traditional gold mining methods and maximizing the utilization of mineral resources.

- Strong Adaptability: Capable of processing both coarse and fine gold ores (suitable for ore with particle size 0.4-0.6mm) and adapting to various beneficiation processes. It performs stably regardless of the flotation properties of the ore.

- Eco-Friendly & Energy-Efficient: Operates without any chemical agents, eliminating environmental pollution risks. With low water and electricity consumption, it reduces production costs while minimizing environmental impact.

- Stable & Reliable Operation: Features a robust structural design that ensures consistent performance even in harsh mining environments. The equipment requires minimal maintenance, reducing downtime and operational hassle.

- Compact & Space-Saving: Adopts a compact design with a small footprint, making it easy to install and integrate into existing production processes without extensive site modifications.

Operating Guidelines

- Preparation Stage

Prior to operation, conduct a comprehensive inspection to ensure the equipment is in optimal working condition. Check all components, particularly the motor and centrifugal cylinder, for any damage, looseness, or abnormal wear.

- Feeding

Feed the ore slurry into the equipment in accordance with the specified parameters: particle size should be controlled between 0.4-0.6mm, and slurry concentration maintained at 30%-50% for optimal separation results.

- Equipment Startup

Start the motor and adjust the rotation speed of the centrifugal inner sleeve. The recommended speed range is 200-560 rpm, which can be fine-tuned based on the particle size of the raw ore to achieve the best separation efficiency.

- Operational Process

Under the action of centrifugal force, gold particles in the ore slurry rapidly settle to the bottom of the inner sleeve and move upward along the spiral grooves. Light gangue minerals are continuously discharged through the light material outlet, ensuring continuous and efficient separation.

- Ore Discharging

Stop the equipment periodically to remove the enriched gold particles from the heavy material outlet. Transfer the collected gold concentrate for further processing as required.

Application Scenarios

- Placer Gold Enrichment: Widely used for enriching placer gold in rivers, streams, and other surface gold deposits.

- Lode Gold Beneficiation: Ideal for gold extraction operations in lode gold mines, supporting efficient beneficiation of hard rock gold ores.

- Eco-Conscious Gold Mining: Perfectly suited for areas with strict environmental protection requirements, thanks to its chemical-free operation and low environmental impact.

Technical Specifications

| Model | qrc-05 | qrc–06 | qrc-07 | qrc–08 | qrc–10 |

|---|---|---|---|---|---|

| Production Capacity (t/h) | 3-5 | 15-30 | 30-40 | 60-80 | 80-120 |

| Ore Feeding Concentration (%) | 10-25 | 13-30 | 22-30 | 50-70 | 80-100 |

| Working Ore Particle Size (mm) | 0-1.5 | 0-2 | 0-2.5 | 0-2 | 0-2 |

| Water Consumption (m³/h) | 4-6 | 15-20 | 25-30 | 50-70 | 70-90 |

| Reverse Water Pressure (MPa) | 0.05 | 0.15 | 0.18 | 0.2 | 0.25 |

| Motor Power (kW) | 3 | 7.5 | 11 | 18.5 | 22 |

| Inner Sleeve Rotation Speed (r/min) | 600 | 450 | 400 | 340 | 300 |

| Weight (kg) | ≈ 200 | ≈ 1000 | ≈ 1800 | ≈ 2600 | ≈ 3000 |

Why Choose Our Water Jacket Gold Centrifugal Concentrator?

Combining cutting-edge centrifugal separation technology with user-centric design, our Water Jacket Gold Centrifugal Concentrator delivers unmatched gold recovery rates, operational stability, and environmental performance. Whether you’re engaged in placer gold mining or lode gold beneficiation, this equipment helps reduce production costs, improve resource utilization, and achieve sustainable mining operations. Backed by reliable after-sales support and easy maintenance, it’s the preferred choice for modern gold mining enterprises worldwide.