Description

Core Features

1. Efficient Large-Scale Screening

Equipped with a large vibrating feed hopper and a drum screen, it can first sieve out waste materials such as large stones over 60cm. Then, through the rotation of the drum screen and combined water supply flushing from the center and sides, it peels off clay and fine mud from the ore, separating gold-bearing fine materials smaller than 20mm. This reduces wear on subsequent mineral processing equipment and meets the needs of large-scale continuous screening.

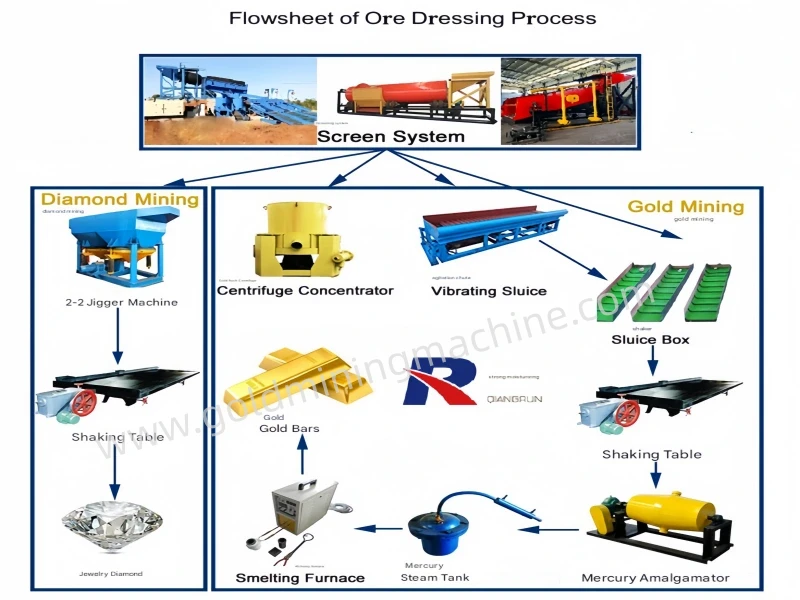

2. High-Recovery Gravity Mineral Processing

It can be equipped with equipment such as a jig chute and a water jacket centrifuge. Using the principle of gravity mineral processing, gold particles settle and concentrate due to their high density. Some models also adopt centrifuge secondary separation, enabling the recovery rate of coarse gold to reach over 95%. The overall gold recovery efficiency is stable, meeting the recovery needs of placer gold of different particle sizes.

3. Flexible and Convenient Transfer Mobility

Most adopt a wheeled chassis, and some can be customized with a tracked chassis. It can be dragged and transferred by a tractor and can also turn 180 degrees in place. It can easily navigate mining areas with complex terrains such as rivers, deserts, and mountainous areas without complicated disassembly, allowing for quick switching of operating locations and saving costs on ore transportation and equipment migration.

4. Integrated Independent Operation

Integrated with core supporting facilities such as generators and water pumps from brands like Weichai, it does not rely on external complex power supply and water supply systems, realizing fully automatic production with one-key start and stop. At the same time, it is equipped with a waste conveyor to avoid tailings piling up at the rear of the equipment, ensuring a continuous and smooth operation process.

5. Adaptation to Complex Ore Operation

The front end of the drum screen is often attached with a washing cylinder containing reamers, which can efficiently wash and peel off impurities for ore with high mud content. The equipment is lined with polyurethane plates, and key components are made of wear-resistant alloy materials, which can withstand harsh mining environments. It is suitable for placer gold mining in different scenarios such as dry beaches and river courses, with a low failure rate.

Applicable Scenarios

Product Features

- Feeding Methods: Multiple feeding methods are supported, such as excavators and loaders.

- Flexible Mobility: Adopts a steerable design, enabling 180° in-situ rotation.

- Durable Tires: All tires are solid forklift tires, featuring excellent wear resistance and durability.

- Enhanced Trommel Screen Design: The front part of the trommel screen is equipped with a washing drum, which extends the material screening process and greatly improves washing and screening efficiency.

- Strong Expandability: Additional gold separation equipment can be equipped, such as vibrating or agitating chutes and centrifuges, to further improve gold recovery rates.

- Optimized Water Supply System:

-

- Internal flushing in the feeding hopper is responsible for initial material washing and pushing materials into the trommel screen.

- Central flushing in the trommel screen performs primary material washing.

- Side flushing of the trommel screen cleans the external fine screen mesh to prevent clogging.

Product Structure

Parameters:

| Parameter | Specification |

| Handling Capacity | 100-120 t/h |

| Feeding Mode | It is recommended to use an excavator |

| Feed Height | 3.7m |

| Maximum Feed | ≤280mm |

| Power (Roller Screen) | 11Kw |

| Power (Sand Pump) | 22KW |

| Speed Reducer | 400# |

| Electric Generator | 70KW |

| Roller Screen | Ø1.5m-1.5m |

| Tires | 6 solid engineering tires |

| Traction Speed | ≤15Km/h |

| Total Power | 33KW |

Reviews

There are no reviews yet.