The Ultimate Showdown in Fine Gold Recovery: Small Gold Dredge Centrifuge vs. Vibrating Screen

I. Introduction: The Fine Gold Recovery Challenge

Recovering fine gold (<100 mesh) is critical to small-scale placer mining profitability, as traditional methods struggle here. Industry data shows ~40% of gold in typical deposits is <150 mesh (100μm), requiring efficient capture technology. The main obstacles for gravity separation are fine gold’s surface area effect and viscous drag.

II. Core Principles: Centrifugal Force vs. Gravity + Vibration

Centrifuge (Centrifugal Concentrator): Relies on high rotational speeds (60-300 RPM) to generate centrifugal force (up to 60G), pressing fine gold against the catch groove wall—overcoming water flow viscous drag. Stable speed is essential for micro-particle separation.

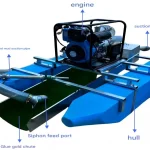

Vibrating Screen + Sluice Box: The vibrating screen classifies and washes ore, while the sluice recovers gold via vibration (1-3mm amplitude, 30-60 cycles/min) that keeps slurry loose. A balanced screen angle (10°~14°) and water flow prevent fine gold loss.

III. Fine Gold Recovery Rate: Quantitative Comparison

Centrifuge: Modern small centrifuges (2-inch/4-inch) achieve ≥98% recovery for <150 mesh fine gold when processing 60-mesh pre-concentrates. It works best as a final concentration stage, not primary sorting.

Vibrating Screen/Sluice: Even high-quality models only reach 80%~90% recovery for <200 mesh gold, with rates dropping as particle size decreases. Riffled rubber mats and regular cleaning (every 2 hours) maximize efficiency.

IV. Operating Condition Adaptability & Production Efficiency

Centrifuge: Strictly requires low clay content (<5% for <5μm clay) to avoid clogging. Operates in batches with low throughput (1-3 tons/hour for 4-inch models), needing shutdowns for concentration (15 mins every 4 hours).

Vibrating Screen: Tolerates high clay content (15%~20%) with effective washing. Ideal for continuous operation, with 6-inch models handling 5-10 tons/hour of raw ore—best for maximizing processing speed.

V. Cost & Operation: TCO and Maintenance

Centrifuge: 30%~50% higher initial cost (due to precision bearings/motors). Requires professional operation (precise speed/water pressure control: 0.05~0.1 MPa) and maintenance (lubricant/seal checks every 500 hours). Auto-timed discharge or VFD systems reduce human error.

Vibrating Screen: Low energy consumption (1.5kW for 4-inch models) but frequent wear part replacement (screens, mats) with annual consumable costs at 5%~10% of equipment price. Simple operation (adjust water flow/angle) and daily maintenance (screen checks, mud cleaning).

VI. Scenario Recommendations & Conclusion

Small Exploration (Limited Budget): 2-inch manual centrifuge (portable, ~15kg) + mini vibrating sluice (2 tons/day capacity). Use “bulk primary sorting (sluice) + fine concentration (centrifuge)” strategy.

Key Optimization Tips: For centrifuges, ensure centrifugal acceleration ≥60G. For vibrating screens, keep excitation force moderate (1mm material jump) to avoid fine gold ejection.

Conclusion: Centrifuges outperform in fine gold recovery but need clean feed and precise operation; vibrating screens excel in throughput, harsh condition adaptability, and initial cost. For commercial profitability, the combined process (vibrating screen primary sorting + centrifuge concentration) is optimal. Decision shortcut: Prioritize <100 mesh gold → Centrifuge; High clay/sediment → Vibrating Screen; Budget allows → Combined process.